Last Updated on April 18, 2021 by James

In the woodworking area itself there are bound to be certain accidents, with a missing finger one of the most common of injuries of them all, be it a professional, homeowner, student, or your regular hobbyist. Surveys estimate around 400,000 accidents while woodworking resulting in a trip to the emergency room.

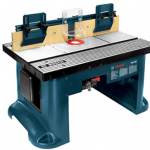

Luckily router tables are among the safer members of the woodworking practices. But just because you’re holding the wood and not the machine itself, it doesn’t mean you go at it without any safety precautions first.

Here Are Some Safety Tips On Using The Router Table.

1. Read the Manual

Every router table provides a safety manual that is specific to the machine itself, going through such a list will help you get first-hand knowledge on not only its special features but also the specific precautions while operating it, whether you’re simply a beginner or a professional.

2. Appropriate Gear

Your clothes should cover enough of your body while not being loose at the same time. Loose clothes and jewelry cause many accidents while woodworking, getting caught in the router and what not. It’s better to simply avoid such accessories and clothes while woodworking.

At the same time, carrying eye protection is necessary, even when your machine is efficient and comes with a dust port. You never know when the cut might just throw some mall wood pieces that could lodge on to your eye, possibly leading to you getting blind.

Other protection gears, like gloves, helmets and such aren’t that necessary, but if you can obtain them, a great bonus.

3. Check Everything Before Starting

Make sure the horsepower, router speed match with the wood selected, regarding the size and the width or depth, along with the bit. The bit should also be checked over before your turn on the machine itself, i.e. if you require a half-inch or a quarter-inch shank, it’s sharpness as well as the cutting length and diameter.

If you’re changing the bits, make sure the entire machine is turned off. Check if the switch is off before you even connect it to the power.

4. Make The Most Of The Fences And The Feather Boards

The fence and the feather board are present to help hold the wood in place for you, and when fixed properly, you won’t even have to hold onto the wooden piece while doing the cuts, making it less likely for you to lose a finger. The fence will come with a guard, make sure you use that as well.

5. Never Force The Router Table.

There are different types of routers, flat tables, and such for certain type of wood. Make sure you’re aware of that before you use it for a wooden piece not suitable to the router, or even the router table.

6. Keep Safe Distance

When turning it on, make sure your body is at least a few inches away from the table. This is a common-sense tip, but there’s nothing wrong with repeating it, considering how much of an important tip this is.

7. Large or Small

Depending on the size of the wooden board, make sure to keep your cautionary levels high. Smaller wooden pieces require more careful attention than larger ones since with bigger pieces you’re less likely to hurt yourself that easily.

8. Be Aware Of The Environment

Working in a dry and cooler wood shop is highly recommended to the wet and damp environment that is a danger to not only the electrical and metal equipment but also your hold on the wood or router. If you’re sweating or are a little wet, you might just slip up to injure yourself.

9. Only Routers

Don’t use any other machine in place of the router just because they’re of the same size and can easily fit the equipment. It’s called a router table for a reason. You don’t know how that is going to work, or if the table will be able to handle the speed or weight of said equipment.

10. Maintenance

Keep your equipment as updated as possible, servicing every minor issue that comes up as well. Your safety, as well as your efficiency, is what matters here the most.

Conclusion :

To conclude, it may be easier than most woodworking machines to handle a router table, but you must still follow the main guidelines of safety when handling a machine that could potentially be hazardous.

Do let us know what you thought of this article in the comment section below.